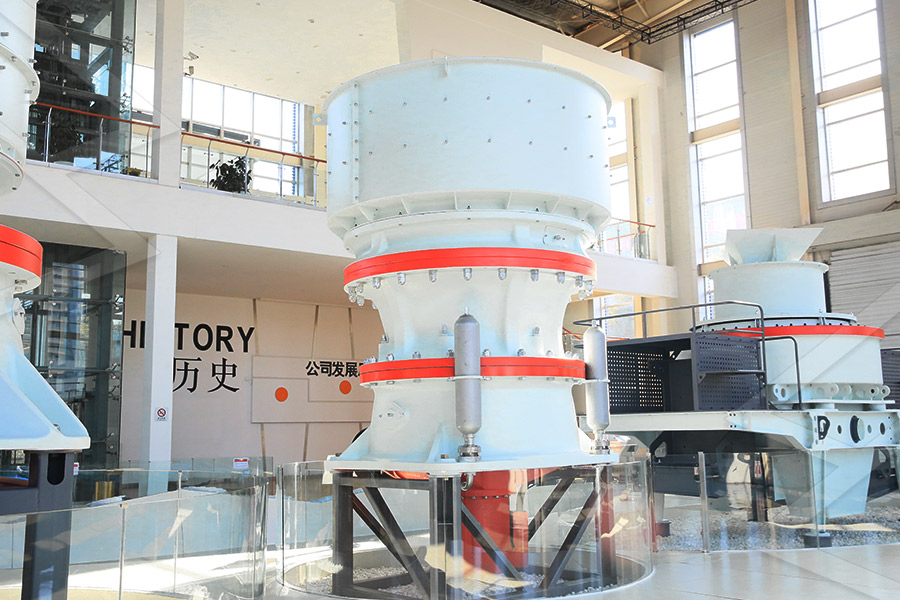

Adjusting Size On Mining Cone Crushing Equment

A Detailed Overview of Cone Crushers and What You Need

How to Adjust a Cone Crusher; Cone Crusher Diagram; Choosing the Right Cone Crusher for Your Quarry and Mining Operations Cone crushers are among the most versatile and useful pieces of aggregate crushing equipment with many of these machines playing an integral role 2021年11月1日 This paper describes a novel size reduction control strategy for cone crushers to address this problem The proposed control strategy is based on selfoptimizing control Size reduction control in cone crushers ScienceDirect2007年2月1日 Multiobjective models of the crushing chamber, output and size reduction based on new output calculation methods, population balance models and interparticle breakage is Multiobjective planning of cone crusher chamber, output and size 2023年2月24日 Proper adjustment of a cone crusher is crucial for its efficient operation and to ensure that it produces the desired product size In this article, we will provide an overview of the steps involved in adjusting a cone crusher How to Adjust a Cone Crusher: A StepbyStep 2025年4月2日 This paper describes a novel size reduction control strategy for cone crushers to address this problem The proposed control strategy is based on selfoptimizing control Size reduction control in cone crushers Tampere 2024年1月28日 If you want to stabilize the output, quality and production line load of sand and gravel products, you must first ensure a consistent cone crusher CSS, otherwise it will easily How to Maximize the Productivity of Cone Crushers Crushing Equipment

Cone Crusher Sizing Selection To Maximize

2023年8月28日 Cone crushers can efficiently produce fine and coarse particle sizes with good shape, making them suitable for aggregate production Be sure to specify the minimum and maximum sizes needed along with the desired 2025年3月3日 Firstly, through precise calculations and simulations, the shape and size of the crushing chamber are optimized to ensure even force distribution on materials during crushing, Working Principle and Maintenance Tips for Cone Crushers2022年8月26日 In most cases, cone crushers provide reduction ratios of 4to1 and up to 6to1 (meaning the ratio of the feed size to the crusher vs the size of the crusher discharge)Maximizing Cone Crusher Performance Machinery Supply2019年7月3日 Compressive crushing has been proven to be the most energy efficient way of mechanically reducing the size of rock particles Cone crushers utilize this mechanism and are CONE CRUSHER MODELLING AND SIMULATIONSymons cone crusher is suitable for hard and midhard rocks and ores, such as iron ores, springs and hydraulic pressure station for adjusting discharge openingadjusting mechanisim on kefid cone crushers MiningGold ore crushing begins when gold ore material from the mine is reduced in particle size by crushing and crushing method continues using a cone crusher and an Rock Crusher Plant Process or Rock Stone Crushing Plantcrushing size using a cone crusher Mining Quarry Plant

adjusting crusher stone sebocomconstructionco

Adjusting A Cone Crusher Processing capacity: 12 1000 t / h Feeding size: 35 300 mm Cone diameter: 6002200 mm Applied materials: Granite, basalt, quartz stone, iron ore, pebbles, green stone, copper ore and limestone Get Price ListContribute to yunan88/crusher development by creating an account on GitHubcrusher/sbm adjust a cone crushermd at main 2025年1月16日 Cone Crusher Parts Jaw Crusher Parts Impact Crusher PartsHow Do You Adjust The Gap on A Cone Crusher? Xiangjian 2023年5月2日 crushing operation, each variant can have a different cavity type, which can be classified into standard type and short head type, or standard type, intermediate crushing type, and fine crushing type Spring Cone Crusher The earliest Simons cone crusher had a spring safety device It is comprised of adjusting sleeve,Cone Crusher Spring Cone Crusher2025年3月25日 4 Hp cone crusher has regulators, so you can adjust the size of crushing particle size easily 5 The kind of mobile crusher for sale also has a spring protection device 6 It has a complete set of lubrication systems When the oil temperature is too high or the flow rate is too slow, the crusher will automatically shut down 7Cone Crusher For Sale Professional Manufacturer Aimix2023年2月23日 A cone crusher is a powerful tool used in the mining, aggregate, and construction industries to crush materials into smaller pieces But how does it work? In this article, we'll explore the cone crusher working principle, including the eccentric motion of the main shaft, the crushing process, and the importance of proper maintenance Whether you're a seasoned Understanding the Cone Crusher Working Principle: How It

How to adjust cone crusher gap? dumajx

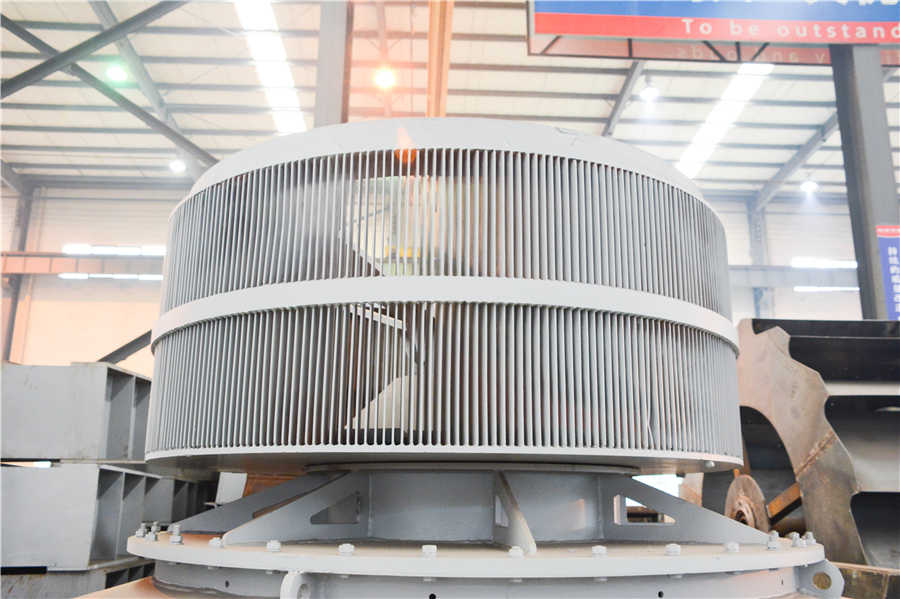

To adjust the crushing performance of a cone crusher, a key factor is to regulate the gap between the cone crushing wall (the moving cone) and the cone crushing bowl (the fixed cone) By raising or lowering the upper shell, this gap can be flexibly adjusted to precisely control the size of the crushed material2015年5月13日 Gentle crushing, ie small size reduction in the last stage, is known to In the mining industry crushing is the first mechanical stage in the process of comminution, in in a cone crusher (PDF) Cone Crusher Performance ResearchGateWhy McLanahan Crushing Equipment McLanahan crushing equipment accepts feeds of large material and reduces the material to the desired product size Because each crusher type has a limited reduction capability, sometimes Crushing McLanahan2021年6月15日 Cone crusher is one of the mainstream crushing equipment in mining industry It is mainly used for medium or fine crushing for various kinds of raw materials The output size of cone crusher is determined by the distance between mantle and concave But many people don’t know much about the discharge adjustment dvice of cone crusher3 Types Of Discharge Adjustment Devices For Cone Crushers Normally the size reduction by crushing is of limited importance besides the top size of the product going to grinding The gape and the width are set values for a given crusher while the setting can be altered to adjust the product size AMIT 135: Lesson 5 Crushing – Mining Mill The cone crusher is a modified gyratory crusher, and accordingly many of the same terms including gape, set, and throw, apply The essential difference is that the shorter spindle of the cone crusher is not suspended, as in the gyratory, but is supported in a curved, universal bearing below the gyratory head or cone (Figure 68)Major suppliers of cone crushers include Metso Cone Crusher an overview ScienceDirect Topics

CRUSHING SCREENING Crushing and Screening

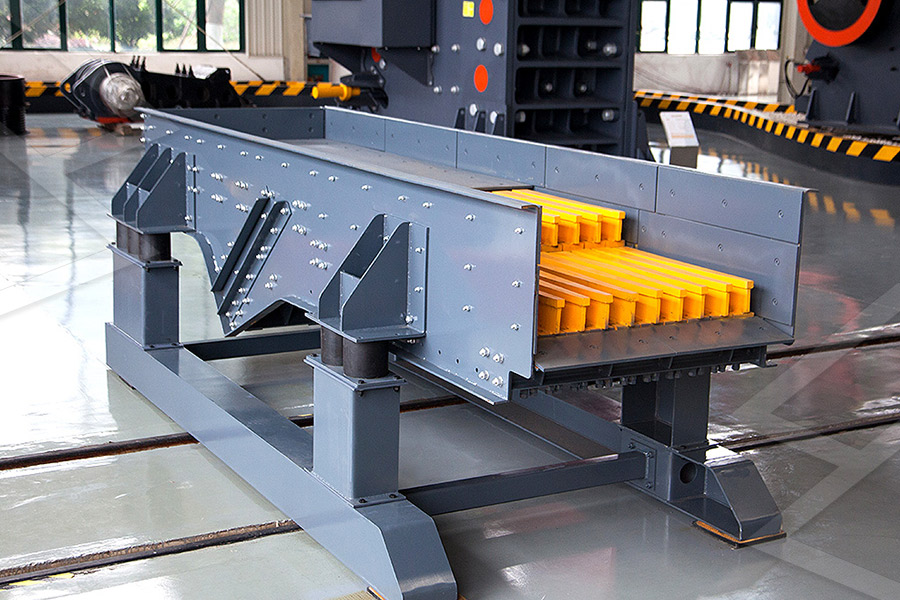

2017年5月30日 design and highgrade cast steel body of our cone crushers provide the strength and stability necessary for crushing extrahard materials while ensuring low maintenance costs 9 MCS 900 MCS 1150 MCH 900 MCH 1150 Max feeding size (mm) 100150 250400 4560 70175 Closed Size Setting (mm) 2544 2448 1032 8年5月29日 The Nordberg® HP Series™ for mining Metso's Nordberg HP Series cone crushers are ideal for many different mining applications In mines, cone crushers are typically needed for crushing to obtain the maximum size reduction ratio and they typically focus on producing material for the downstream processNordberg HP Series cone crushers – High performance Cone crushers are generally found in use for secondary, tertiary, and downstream crushing services, with jaw crushers and gyratory crushers used for primary crushing operations Jaw, Cone and Gyratory Crushers In some cases, the Run of Mine (ROM) ore from the mine can be fed to a cone crusher via conveyors and screens, but more often, the feed Cone Crushers (Parts of a Cone Crusher) Explained saVRee2015年7月18日 Coarse crushing includes crushing operations discharging at sizes 4 to 6in or coarser; intermediate crushing comprises operations taking feeds 6 or 8in maximum and making products down to 1/2″ or 3/8″ Fine crushing is reduction by crushing to 1/4″ or finer; the distinctions are not sharpRock Crushing Process in Mining 911Metallurgist2017年7月4日 When it comes to cone crushing material, a full chamber is the best practice {{image4a:lw:635}} • Correct application Cone crushers are versatile machines, but using them as they are set up to function is the best idea A 4:1 reduction ratio is Caring for your cone crusher: A guide to optimising performanceNordberg® MP Series™ cone crushers have a high capacity and the highest crushing force of any cone crusher of similar size Thanks to their crushing force, Nordberg® MP Series™ cone crushers are widely used in the secondary and tertiary crushing stages in mining operations that process very large amounts of material Metso MX™ Series Cone crushers for demanding crushing needs Metso

Cone Crusher Sizes Crusher Mills, Cone Crusher, Jaw Crushers

Cone Crushers – Tecnocava – Italy – Maps – Vibrating Screen Cone Crusher, TELSMITH 489S ; type Girasphere (B Style); size feed lump 80÷150/200 mm ; se no 7140 year 1969 ; capacities of 0÷40 mm to 80÷150 MTPH ;2024年9月24日 according to the size of the crusher to be adjusted Example: If the measurement of the OSS in the C160 model is 191mm (7 1/2”), then the CSS will be: 191 41 = 150 mm (7 1/2” – 1 5/8” = 5 7/8”) By determining the CSS, we will know the closed side setting of the crusher instead of opening ofMeasuring the crusher setting 911 MetallurgistStone Crusher JXSC company stone rock crushers include cone crusher, jaw crusher, impact crusher, mobile crusher, sand making machine, mobile crushing plant hammer crushing which can crush with more than 200 kinds of Stone Crusher Cone Jaw Crushers Machine Prompt : Caesar is a famous mining equipment manufacturer wellknown both at home and abroad, major in producing stone crushing equipment, mineral separation equipment, limestone grinding equipment, etcHenan Mining Machinery and Equipment Manufacturer Adjust 2025年3月17日 5High crushing ratio, high efficiency and energy saving, many crushing cavities, convenient cavity cleaning and solid structure 6It can quickly adjust the size of crushing discharge particle size by regulator 7With complete lubrication system, it will automatically shut down when the temperature is too high or the flow rate is too slowcone crusher,Spring cone crusher factory walker mining2017年3月4日 With the rapid development of mining techno logy, the cone crusher can be divid ed into four types: Large feesing size ,high crushing cavity,w ide range of the highhardness of the materials (PDF) SIZE REDUCTION BY CRUSHING METHODS

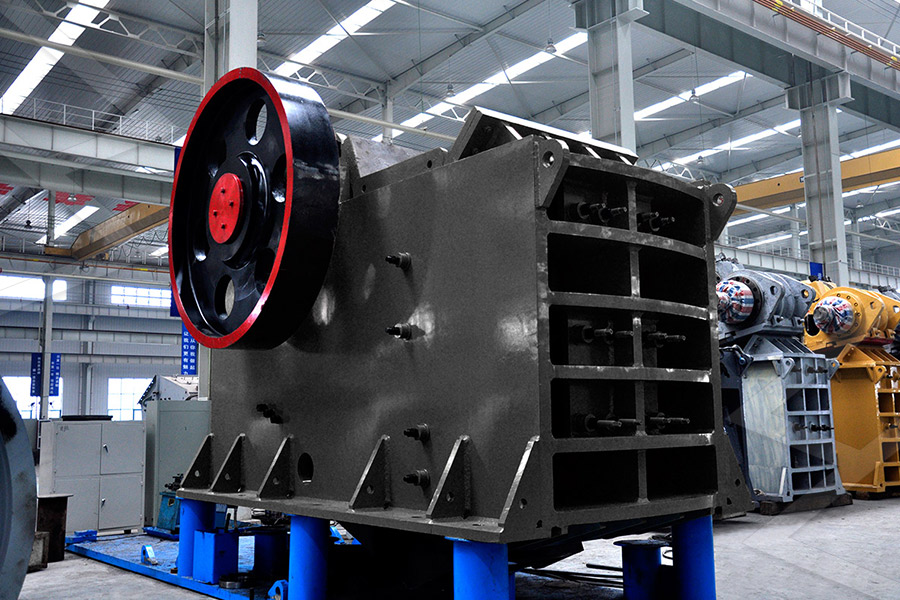

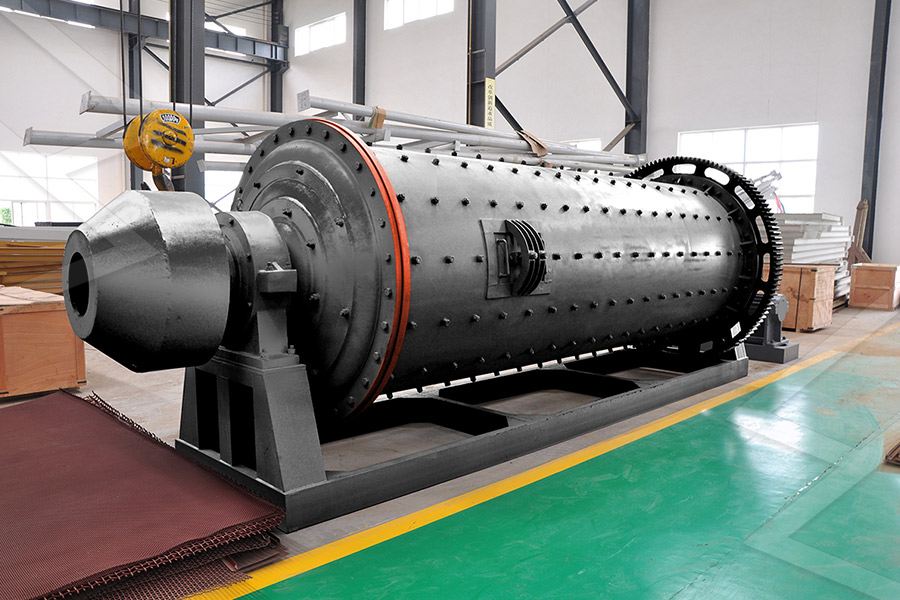

Types of Crushers Explained: Everything You Need to Know

2024年4月19日 The crushing process is commonly conducted in several stages Each stage of the crushing process implements a different type of crusher to gradually reduce the size of the material The first step is crushing the material by using larger crushers that can reduce the material into smaller sizes that will be used in the next stageThe cone series crushers compress stone/rock mineral materials by squeezing force between the fixed shaft and moving shaft Change the least gap between the two crushing shafts of the equipment can adjust the target particle size When the wedge or eccentric rotator starts to work, compression comes into being within the cavityCone Crusher Mine Crushing Equipment JXSC MineCrushing 101 Masaba Cone Crusher 8 1 maximum reduction ratio for compression crushing and is normally used as a secondary or tertiary crusher Lower wear cost than imp actors Good capacity down to around ½ Production drops off dramatically when producing smaller materials Even with the new high speed high throw cones Cones can vary from 60 adjusting cone crusher top head bhlautomationcccoSymons cone crusher is suitable for hard and midhard rocks and ores, such as iron ores, springs and hydraulic pressure station for adjusting discharge openingadjusting mechanisim on kefid cone crushers MiningGold ore crushing begins when gold ore material from the mine is reduced in particle size by crushing and crushing method continues using a cone crusher and an Rock Crusher Plant Process or Rock Stone Crushing Plantcrushing size using a cone crusher Mining Quarry PlantAdjusting A Cone Crusher Processing capacity: 12 1000 t / h Feeding size: 35 300 mm Cone diameter: 6002200 mm Applied materials: Granite, basalt, quartz stone, iron ore, pebbles, green stone, copper ore and limestone Get Price Listadjusting crusher stone sebocomconstructionco

crusher/sbm adjust a cone crushermd at main

Contribute to yunan88/crusher development by creating an account on GitHub2025年1月16日 Cone Crusher Parts Jaw Crusher Parts Impact Crusher PartsHow Do You Adjust The Gap on A Cone Crusher? Xiangjian 2023年5月2日 crushing operation, each variant can have a different cavity type, which can be classified into standard type and short head type, or standard type, intermediate crushing type, and fine crushing type Spring Cone Crusher The earliest Simons cone crusher had a spring safety device It is comprised of adjusting sleeve,Cone Crusher Spring Cone Crusher2025年3月25日 4 Hp cone crusher has regulators, so you can adjust the size of crushing particle size easily 5 The kind of mobile crusher for sale also has a spring protection device 6 It has a complete set of lubrication systems When the oil temperature is too high or the flow rate is too slow, the crusher will automatically shut down 7Cone Crusher For Sale Professional Manufacturer Aimix2023年2月23日 A cone crusher is a powerful tool used in the mining, aggregate, and construction industries to crush materials into smaller pieces But how does it work? In this article, we'll explore the cone crusher working principle, including the eccentric motion of the main shaft, the crushing process, and the importance of proper maintenance Whether you're a seasoned Understanding the Cone Crusher Working Principle: How ItTo adjust the crushing performance of a cone crusher, a key factor is to regulate the gap between the cone crushing wall (the moving cone) and the cone crushing bowl (the fixed cone) By raising or lowering the upper shell, this gap can be flexibly adjusted to precisely control the size of the crushed materialHow to adjust cone crusher gap? dumajx

(PDF) Cone Crusher Performance ResearchGate

2015年5月13日 Gentle crushing, ie small size reduction in the last stage, is known to In the mining industry crushing is the first mechanical stage in the process of comminution, in in a cone crusher