Feedind System To Mining Mill Cement Plant

Raw Mill Feeding Cement Plant Optimization

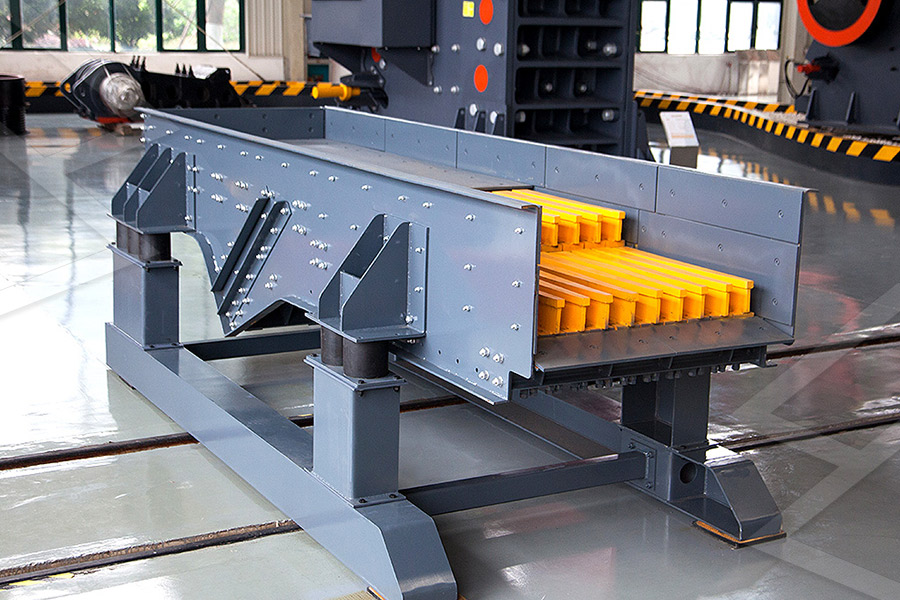

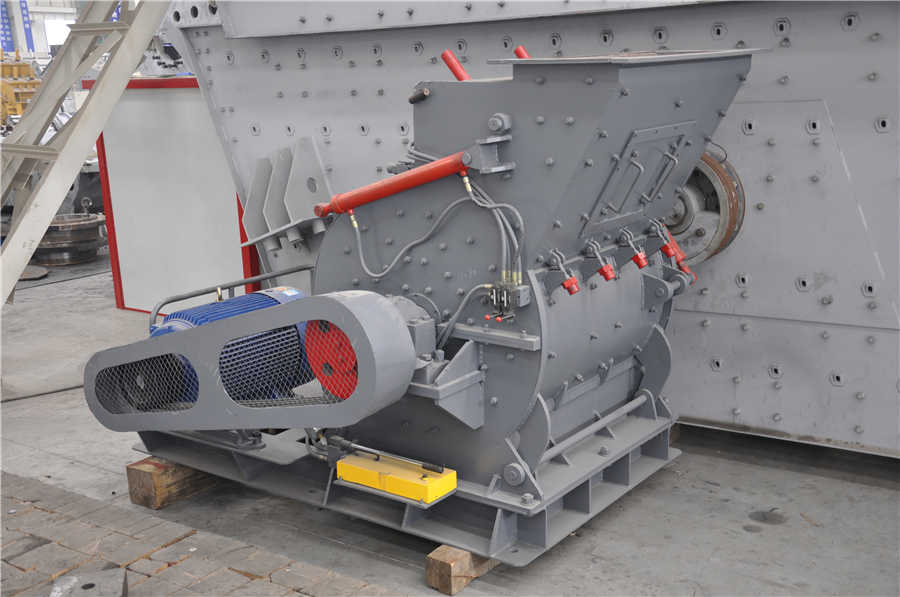

After monitoring and controlling the quality of incoming raw material, the area of high activity for quality department to ensure quality mix for smooth production of high quality of cement is “mill feeding system” The system consists of material hoppers/bins, weighing, conveying, venting Cement mill feeding section facilitates a reliable feeding of clinker, gypsum and other additive like limestone, slag, fly ash etc Mill feeding consists of material hoppers, weighing, conveying to millCement Mill Feeding Cement Plant OptimizationIn cement manufacturing, maintaining consistent raw mill and kiln feed quality is crucial for the efficient operation of the plant Variability in feed composition can lead to inefficient energy Raw Mill and Kiln Feed Consistency: Key to Efficient Cement 2023年7月21日 The raw material grinding system of cement plant uses limestone, clay and copper tailings to feed the ball mill, and feeds with apron feeder The materials of the three How Is The Cement Apron Feeder Feeding System Upgraded2025年3月22日 The Cement Plant Operations Handbook is a concise, practical guide to cement manufacturing and is the standard reference used by plant operations personnel worldwide The Cement Plant Operations Handbook International Whether kiln feeding or additive feeding to the raw or finish mill, the robust design of Pfister FRW rotor weighfeeders is ideal for dosing powdered bulk materials such as raw meal, fly ash, bypass chloride or kiln dust or cement products Feeding equipment for a modern dry kiln line

Blending systems and control technologies for cement raw

In a cement plant, the preparation of ontarget, uniform kiln feed requires certain tasks to occur in unison Typically, this involves stockpiling/preblending, proportioning, grinding, and Arrangement of metal detector and magnetic separator is integral part of feeding system in vertical roller mills and roller presses Both are installed on mill feeding belt conveyor Coal Grinding Cement Plant OptimizationA large cement factory as an example, according to the requirements of process and control parameters of production line of raw mill, this paper researches and designs the automatic Cement Raw Mill Based on PCS7 and PROFIBUS Production Line Automation In one of Turkey’s leading cement production facilities, we have successfully completed the automation project for the dosing of clinker materials in the stock area and their transfer to the mill In this project, automation systems have CEMENT MILL PREFEEDING SYSTEM GNC After cooling, the clinker may be stored temporarily in a clinker store, or it may pass directly to the cement mill The cement mill grinds the clinker to a fine powder A small amount of gypsum a form of calcium sulfate is normally Cement manufacturing components of a Feedind system to crusher cement plant , feedind system to crusher cement plant the installation of handling system for rdf in a cement plant is challenging as these are mostly upgrades for existing orker safety series concrete manufacturing , more than 250,000 people work in concrete manufacturing over 10 percent of those workersfeedind stage to crusher gypsum plant codomilimetra

Mining Grinding and Processing WEG

Constant speed Low speed synchronous motors Synchronous motors are widely used in mill driving systems at a constant speed using an air clutch between the motor shaft and mill p2015年10月22日 It describes 10 key steps: 1) limestone crushing and storage, 2) raw material dosing, 3) raw material grinding, 4) raw material homogenizing silo and kiln feeding system, 5) clinker calcining system and exhaust gas treatment, 6) clinker storage, gypsum crushing and cement dosing, 7) cement grinding, 8) cement storage, 9) cement packing and bulk Cement Plant Process and Instruments Used PPT SlideShare2022年7月4日 It does both mining of limestone and cement manufacturing The industry started manufacturing cement in 1997 bringing into the cement market two brands called AKSHAR and BUILDPLAST cementMining Activities, Cement Production Process and Quality 2024年2月11日 A cement manufacturing facility is an extension of a cement mining process, as cement plants are usually central to the minerals needed to make the cement This reduces transportation expenses and overcomes the cost of the cement Cement is transferred from grinding mills to silos (big storage tanks), which pack 20 to 40 kg bags Most of All Stages of Cement Manufacturing from The Cement Mining 2012年4月30日 The objective of this article is the development of a novel raw material mix proportion control algorithm for a cement plant raw mill, so as to maintain preset target mix proportion at the raw (PDF) Process Automation of Cement Plant ResearchGate2023年9月22日 Techflow’s Air Pollution Control Products for Cement Plants 1 Electrostatic Precipitator (ESP) for Cement Industry Electrostatic Precipitators (ESPs) are formidable weapons in the battle against air pollution ESP are used in Raw Material Crusher, Cement Mill, Coal Mill, Rotary Kiln in Cyclone Preheater TowerAir Pollution Control in Cement: Solutions Impact Techflow

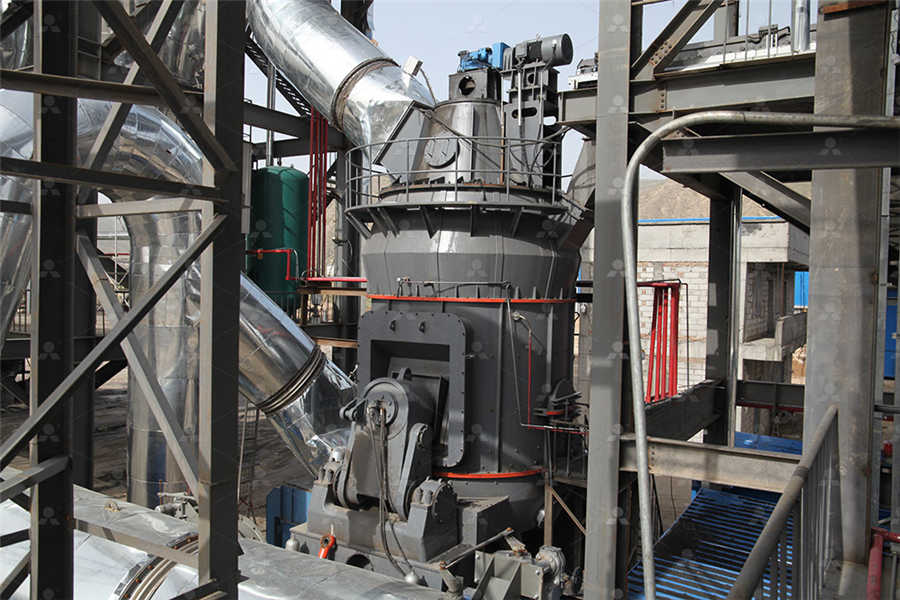

How Is Cement Produced in Cement Plants Cement Making

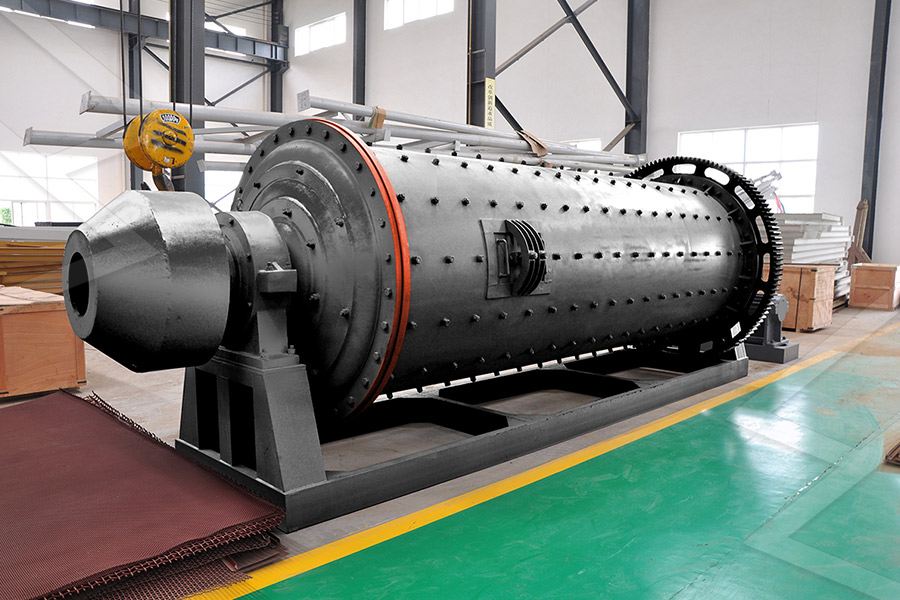

The cyclone preheating system Phase IV: Calcination The calcination is the core phase of the cement making dry process The calcination of the preheated raw meal takes place in the rotary kiln of the cement plant The rotary kiln is a huge rotating furnace in which the raw meal is heated up to 1450 ⁰C and turned to clinkerRaw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plantIn the cement manufacturing process, raw mill in cement plant grind cement raw materials Raw Mill, Cement Raw Mill, Raw Mill In Cement 1987年8月1日 Ball mill control Automatic startup control In most cement plants, start up of a mill is conducted through a series of manual operations on the part of an operator The operator switches on the mill, starts the mill feed and , after ascertaining that the mill load becomes stable , changes the control mode to the constantvalue feedback Optimization of Cement Manufacturing Process ScienceDirect2015年4月14日 The USGS said that many of the country's cement plants were unable to operate at full capacity due to unreliable energy sources and a lack of infrastructure 11 In 2012, Myanmar consumed 4Mt of cement The Myanmar Investment Commission is eager for more new cement plants to be built, approving plans from a variety of investors in recent yearsThe cement industries of southeast Asia Global Cement2025年3月31日 Nowadays, in the field of cement grinding system of the world cement industry, the major cement grinding equipments include loop flow ball mill, roller press, ball mill semifinishing system, and vertical mill system, in which ball mill and vertical mill are 2 major cement grinding systems in Cement Manufacturing PlantsPower consumption of cement manufacturing plant2020年7月4日 14 Cement Mill and Bag House Clinker, along with additives, is ground in a cement mill The output of a cement mill is the final product viz Cement In a cement mill, there is a cylindrical shell lying horizontal which contains metallic balls and as it rotates, the crushing action of the balls helps in grinding the clinker to a fine powderBASIC CEMENT PLANT LAYOUT – Process Cement Forum The Cement

Control in Cement Production ScienceDirect

1983年1月1日 This latter task can be solved by a conventional mill control system will be shown at the cement grinding later The chemical composition control of the raw meal is necessary, because the relative amounts of C2S, C3S, C3A and C4AF formed in the kiln strongly depend on the oxide composition of the ground mixCement Manufacturing Process by TIZITA MOGES , SELAMU ABULE DEREJE ENDALAMAW IF YOU NEED THIS GUIDE AND ALL OTHER USEFUL EXCEL SHEETS WHICH WILL MAKE YOU MASTER THE PRODUCTION , PROCESS , MAINTENANCE ACTIVITY IN YOUR CEMENT PLANT KINDLY CLICK HERE Raw Material Preparation and Cement Manufacturing Process INFINITY FOR CEMENT EQUIPMENT2020年8月25日 Cement equipment refers to all equipment in the cement plant, such as cement mill, cement crusher, cement kiln, cement silo, Using explosion or getter loader to mine raw materials; There are three steps of the hightemperature system: Drying or preheating, calcining, and sintering Cement Manufacturing Process AGICO CEMENT Cement Plant2023年11月1日 The design of the cement grinding system is also focused on “energy saving”, because the cement grinding part accounts for about 45% of the electricity consumption in the cement plant There are many cement grinding system processes to choose from, including open flow grinding, ordinary closed circuit grinding, pregrinding, combined 8 Tips For Cement Plant DesignA cement ball mill is ready for transportation There are many kinds of industrial equipment used in a cement plant, including thermal equipment, grinding equipment, dust removal system, transportation system, storage system, and so onWhen placing an order, we may need to order different equipment from multiple manufacturers at the same timeHow to Start a Cement Factory AGICO Cement Plant2024年1月5日 Ball mills are tube mills used for grinding materials like cement and involve several components The document discusses the movement of grinding media in ball mills, optimal ball charge and filling levels, key Cement ball mill process calculation pdf PPT

OPTIMIZATION OF CEMENT GRINDING OPERATION IN

2021年4月27日 handled by the plant’s maintenance crew Upgrading the classifier and baghouse involves capital expenditure with a high benefit to cost ratio Optimization is especially important when multiple products are being produced Operation and Elements of a ClosedCircuit Ball Mill System Cement ball mills typically have two grinding chambersTo Download Everything About Cement crushers , Kilns , Vertical mill , Cement mill , ETC kindly click here now Preamble It is said that cement manufacture begins in the quarry (Figure 11), which is the commonly used term for Basics of mineral resources for cement production2025年4月3日 Attrition Mill; Blade Mill Washer; Coarse Material Washer; Concrete Washout Systems » Portable Plants Whether its an individual plant to fit an existing application or a whole integrated spread, we're ready to customize your new wheeled plant Close; Fusion Modular PlatformsFeed Conveyors Conveying Equipment Superior Industries2023年11月1日 Cement plants of tomorrow will have to implement all CO 2 abatement and saving measures to the best extent possible Reducing the clinker factor, optimising the reactivity of the clinker, substituting fossil fuels by alternative fuels and using alternative raw materials are pathways which will still play a growing role in future cement productionThe cement plant of tomorrow ScienceDirectFor a cement mill: intermediate or outlet diaphragm For the case of; cement mills with a drying chamber see raw mills Mill working conditions: ventilation air speed through the mill Bigger or smaller than 12 [m/s] Material abrasivity The [%] of slag or pouzzolana content on the fresh mill feed for cement grindingEverything you need to know about clinker/cement Grinding2022年3月8日 costs Based on the above concept a control system is developed for the kiln mill drive used in Cement Industry using PLC, and which can be interfaced using SCADA 1 Introduction In cement plants, variable frequency drives provide controlled torque and speed to the kiln In addition to enhanced process control, the VFD increases the life ofAutomation of Kiln Mill Drive in Cement Industry using

Selection of AC Induction Motors for Cement Plant

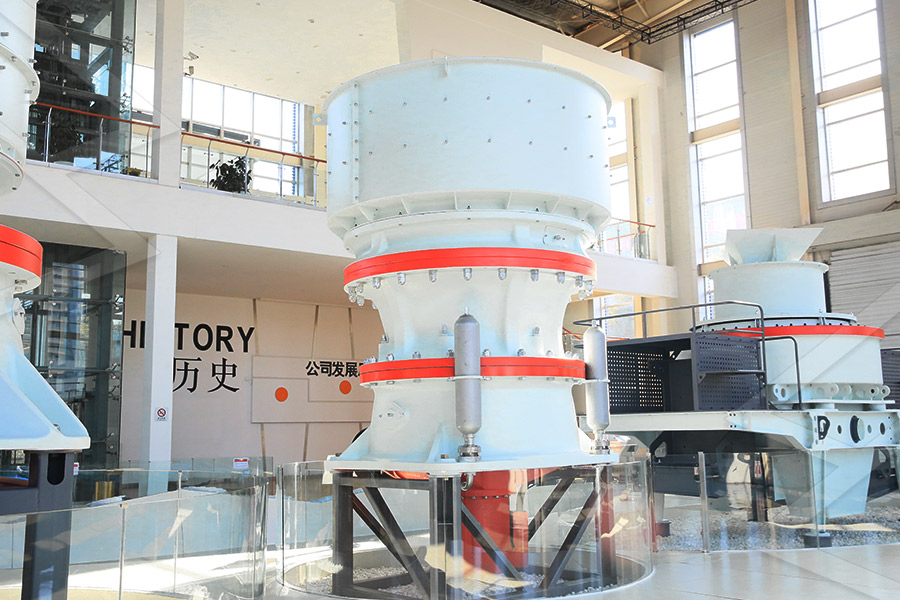

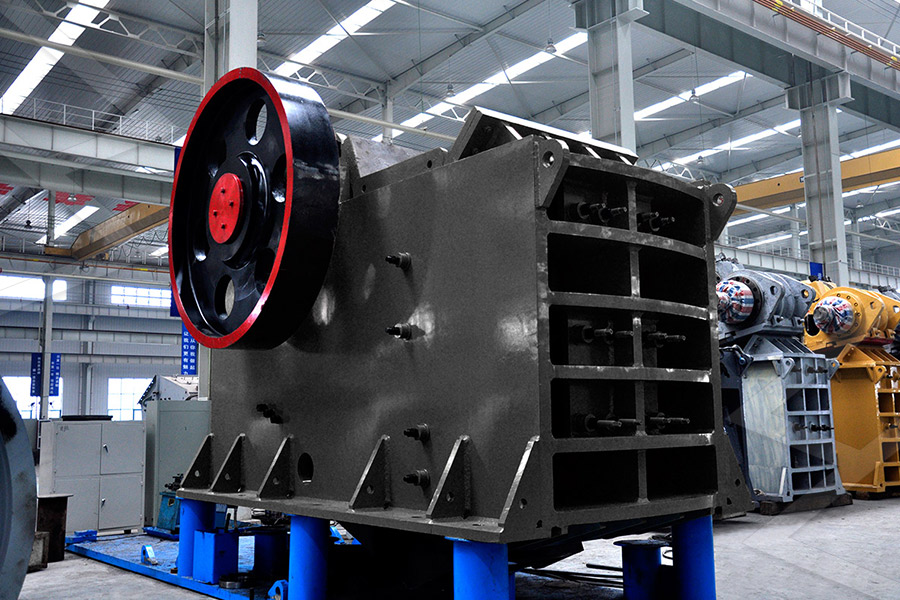

In cement plants, proper specification and supply of AC induction motors is critical to project schedules and providing efficient production This paper focuses on the selection of AC induction motors for cement mill applications, with reference to fan, kiln and vertical mill applications The criteria for motor selection includes:Jaw crusher is mainly used for raw material coarse and medium crushing in the cement plant and crushing plant According to the width of the feed port, it can be divided into three types: large type (feed port is larger than 600mm), the medium type (feed port is between 300600mm), and small type (feed port is smaller than 300mm)feedind Sistema Para Crusher Cement Plant cálcioThe vertical cement mill is largescale cement grinding machine With advantages of energyefficient and stable quality, vertical roller mill is widely applied to many industries, such as cement, power, metallurgy, chemical and nonmetallic mining industry and etc As a typical type of Cement Mill, vertical cement mill set crushing, drying, grinding, grading transportation in one, it grind Vertical Cement Mill, Vertical Roller Mill Buy Cement Cement PlantAfter cooling, the clinker may be stored temporarily in a clinker store, or it may pass directly to the cement mill The cement mill grinds the clinker to a fine powder A small amount of gypsum a form of calcium sulfate is normally Cement manufacturing components of a Feedind system to crusher cement plant , feedind system to crusher cement plant the installation of handling system for rdf in a cement plant is challenging as these are mostly upgrades for existing orker safety series concrete manufacturing , more than 250,000 people work in concrete manufacturing over 10 percent of those workersfeedind stage to crusher gypsum plant codomilimetraConstant speed Low speed synchronous motors Synchronous motors are widely used in mill driving systems at a constant speed using an air clutch between the motor shaft and mill pMining Grinding and Processing WEG

Cement Plant Process and Instruments Used PPT SlideShare

2015年10月22日 It describes 10 key steps: 1) limestone crushing and storage, 2) raw material dosing, 3) raw material grinding, 4) raw material homogenizing silo and kiln feeding system, 5) clinker calcining system and exhaust gas treatment, 6) clinker storage, gypsum crushing and cement dosing, 7) cement grinding, 8) cement storage, 9) cement packing and bulk 2022年7月4日 It does both mining of limestone and cement manufacturing The industry started manufacturing cement in 1997 bringing into the cement market two brands called AKSHAR and BUILDPLAST cementMining Activities, Cement Production Process and Quality 2024年2月11日 A cement manufacturing facility is an extension of a cement mining process, as cement plants are usually central to the minerals needed to make the cement This reduces transportation expenses and overcomes the cost of the cement Cement is transferred from grinding mills to silos (big storage tanks), which pack 20 to 40 kg bags Most of All Stages of Cement Manufacturing from The Cement Mining 2012年4月30日 The objective of this article is the development of a novel raw material mix proportion control algorithm for a cement plant raw mill, so as to maintain preset target mix proportion at the raw (PDF) Process Automation of Cement Plant ResearchGate2023年9月22日 Techflow’s Air Pollution Control Products for Cement Plants 1 Electrostatic Precipitator (ESP) for Cement Industry Electrostatic Precipitators (ESPs) are formidable weapons in the battle against air pollution ESP are used in Raw Material Crusher, Cement Mill, Coal Mill, Rotary Kiln in Cyclone Preheater TowerAir Pollution Control in Cement: Solutions Impact TechflowThe cyclone preheating system Phase IV: Calcination The calcination is the core phase of the cement making dry process The calcination of the preheated raw meal takes place in the rotary kiln of the cement plant The rotary kiln is a huge rotating furnace in which the raw meal is heated up to 1450 ⁰C and turned to clinkerHow Is Cement Produced in Cement Plants Cement Making